Premium Manufacturer of Custom School Uniform

- Home -

- Manufacture

Smart Manufacturing

for Large-Scale

School Uniforms

Quality and Quality Assurance

Intelligent, Fully-Integrated Production Line

Raw material/auxiliary material warehouse

By keeping a wide range of certified fabrics and standardized accessories in stock, we shorten lead times, improve supply chain efficiency, and guarantee that every school uniform is produced with durable, compliant, and high-performance materials.

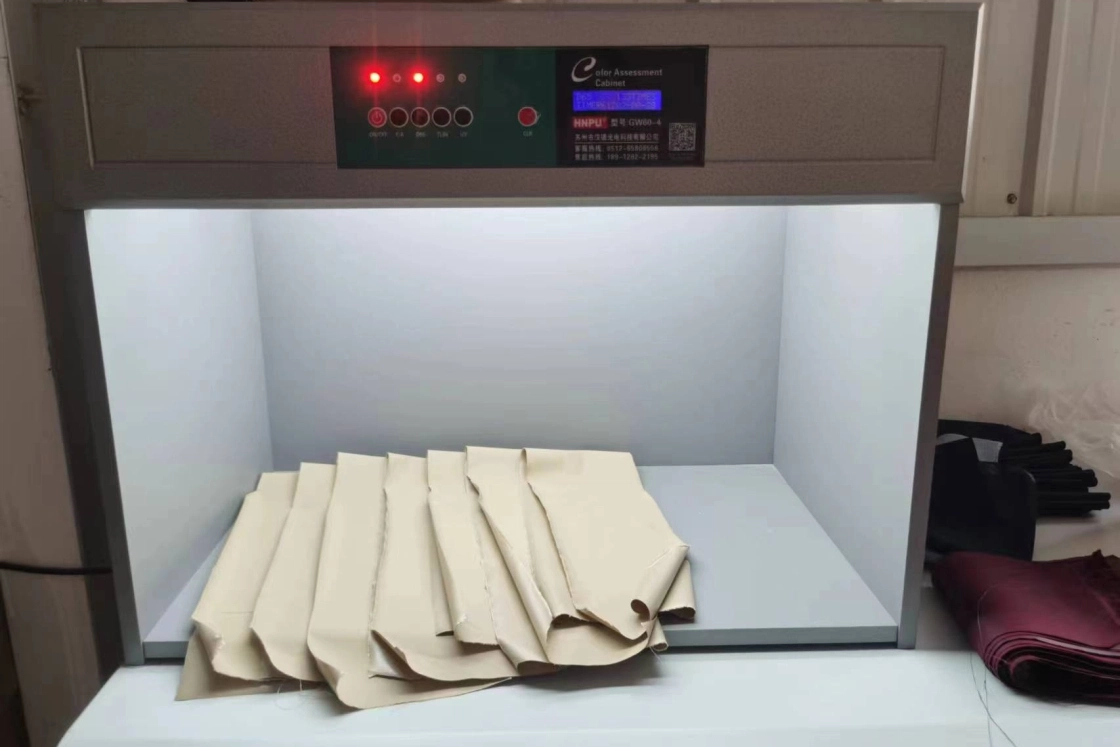

Fabric Inspection

All incoming fabrics undergo strict inspection for color accuracy, shrinkage, hand-feel, and surface defects. This quality control step ensures every material meets production standards before entering the cutting and sewing stages.

Sample Area

Our sample development process ensures each design is accurately translated into a physical prototype. We refine fabrics, colors, trims, and fit details, enabling schools and partners to confirm every aspect before mass production begins.

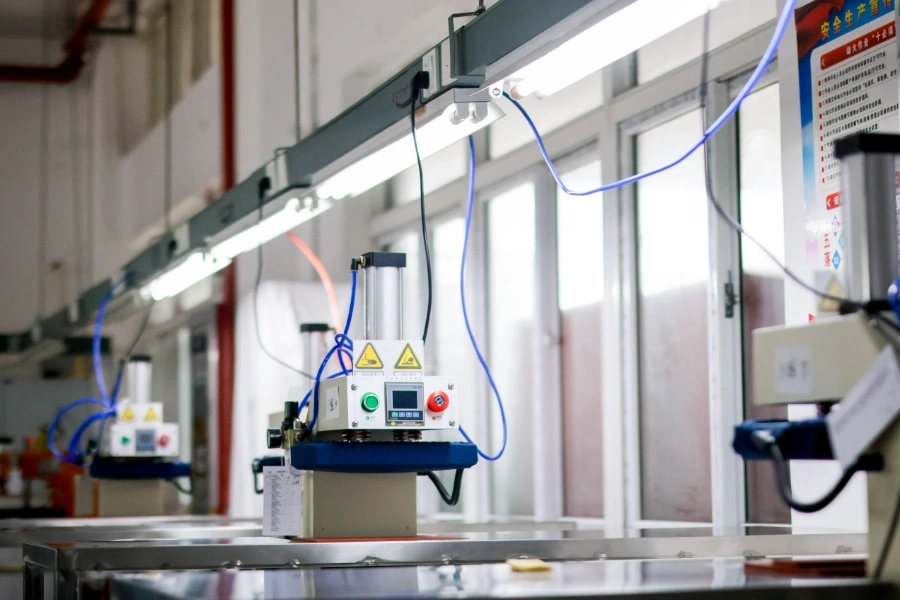

Fabric Cutting Area

Our fabric cutting process combines automated spreading and digital cutting systems. Each fabric batch is verified for shrinkage and color consistency before cutting, which ensures every school uniform enters the sewing stage with stable, high-quality components.

Sewing Area

Our sewing lines combine skilled craftsmanship with standardized procedures to ensure consistent stitching, reinforced seams, and durable construction across all school uniform styles.

Embroidery Area

Logos, emblems, and decorative elements are produced using high-precision embroidery machines. Each design is calibrated for clarity, durability, and consistent color to reflect the school’s identity with professional detail.

Pressing & Finishing

Each uniform is professionally pressed and shaped to ensure a clean, neat appearance. The finishing stage enhances fabric smoothness and presentation, preparing the uniforms for packaging and delivery.

Labeling & Packaging Area

All care labels, size labels, and brand tags are produced and applied with strict accuracy to ensure compliance with international standards. Each label is clearly printed, securely attached, and matched to the corresponding garment to support smooth inventory tracking and professional presentation.

Final Inspection Area

Every garment passes a comprehensive final inspection covering measurements, stitching quality, appearance, and labeling. This ensures that all finished uniforms meet strict quality and durability requirements.

Warehousing Area

Finished uniforms are stored in a clean, climate-controlled warehouse with digital inventory management to maintain product quality and ensure rapid order fulfillment. Each item is carefully packaged and organized by style, size, and school, enabling efficient picking, packing, and on-time delivery.

Sustainable Development

Eco-Friendly Colored Woven Fabric

Crafted from sustainable “zero-dye” fiber blends, this fabric offers exceptional colorfastness without fading. The finishing process adopts a waterless technology, saving water and energy while reducing emissions for a truly eco-friendly solution.

Green & Sustainable

Water, carbon, and energy saving, Eco-friendly fiber materials, Zero discharge of hazardous chemicals

Healthy Zero-Dye

Solution-dyed “zero-dye” technology, Excellent colorfastness and precise color matching, Wide range of color diversity, Stronger sustainability performance